Everything about Motorcycle Parts New Zealand Specialists

Table of ContentsNot known Facts About Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists StatementsThe Best Guide To Motorcycle Parts New Zealand SpecialistsMore About Motorcycle Parts New Zealand SpecialistsLittle Known Questions About Motorcycle Parts New Zealand Specialists.What Does Motorcycle Parts New Zealand Specialists Mean?The 8-Second Trick For Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

Reach out to one of our specialists today.CNC machining innovation is rapidly ending up being the focal point of various production procedures around the globe as a straight result of its many advantages over other approaches. Furthermore, the industries that make motorbikes have actually gotten on board with this fad. The most cutting-edge business are currently establishing their engine parts and wheels making use of machining methods originally developed for motorcycle parts.

On the various other hand, the effects of sector are the primary emphasis of this article. Let's obtain straight right into it. You may be asking yourself why we utilize. It is not hard to fathom the aspects that resulted in this outcome. Now that we have your interest let us discuss the reasoning behind this contemporary advancement in the bike manufacturing market.

Motorcycle Parts New Zealand Specialists for Dummies

In addition, you have total control over the look of the elements, also down to the minute details. Occasionally, motorcyclists may decide to spruce up their experience by mounting aftermarket components or customizing the bike's makeover.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

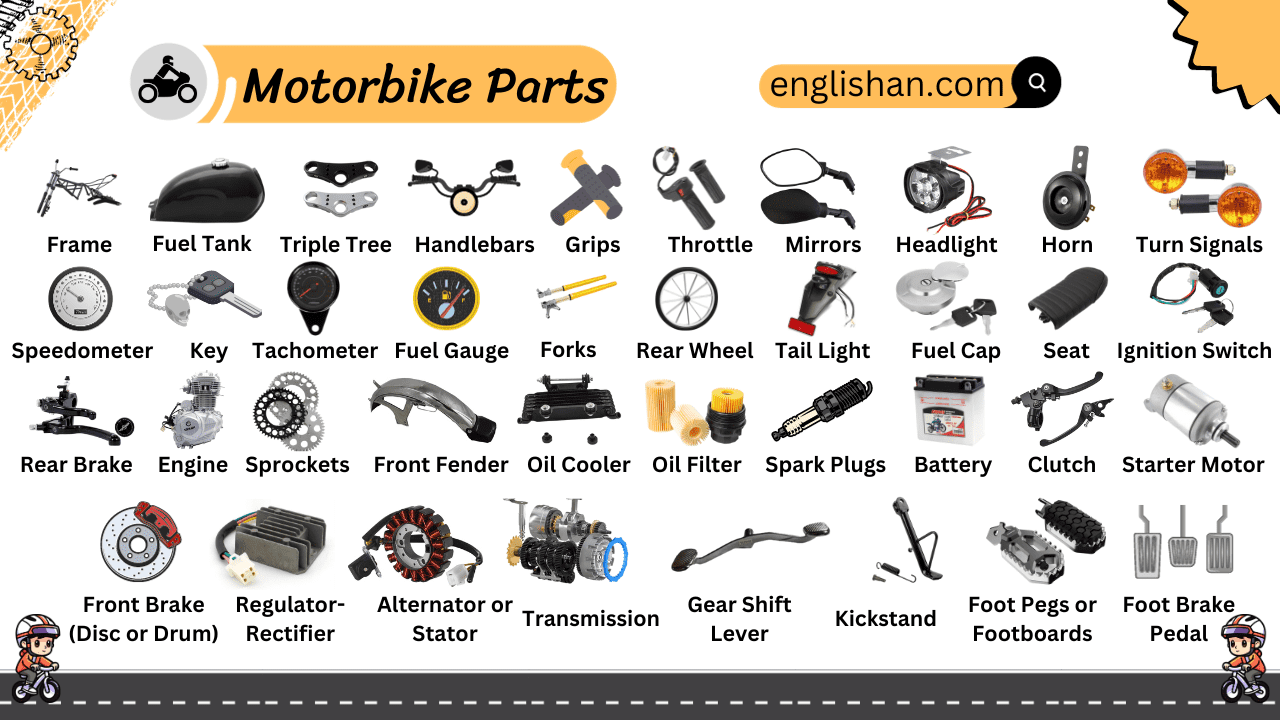

CNC machining might be made use of to make mostly all of a motorbike's steel and plastic components. To proceed, we'll go over numerous machined parts for motorbikes. Unlike those on autos, wheels on motorbikes have a tendency to be a lot more evident. Therefore, the bike's appearances might be improved with the suitable personalization of these wheels.

Milling procedures are used to get the wanted level of wheel customization. Another aspect of the motorcycle that might be customized is the tires.

Top Guidelines Of Motorcycle Parts New Zealand Specialists

When it comes to a car (or a motorbike), one of the most important element is the engine. A number of individuals mention it as the "heart" of the automobile. On the other hand, the camshaft, the cylinder head, and the pistons tend to be detailed and need layouts with a high level of precision.

Use just high-grade items, nonetheless, considering that these lights are important for the safety and security of motorcyclists and various other vehicle drivers or people on the road, particularly at evening. Motorcycle headlights have 3 major parts: the light bulb, or light resource, the lens, and the housing.

Milling procedures with a remarkable coating would certainly result in the lenses having a Read Full Article reflective high quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of breakable products; instead, it is constructed out of difficult polymers that can be machined into more complex patterns.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Motorcycle makers usually cast these parts, however just for the manufacturing of bespoke components. Machining on 5 axes in today's world is the means by which any kind of style shape may be understood.

The success of the procedure is contingent on the mill cutters' capacity to compute subtle and difficult angles properly. Choose Runsom for your tailored motorcycle parts! We have the capacity to produce complicated and fashionable parts making your bike unparalleled. Most are crafted from aluminum or steel alloys, each of which has its uses and benefits.

Below are a couple of instances of steels frequently used in motorbike element machining. Aluminum is the key product made use of by companies specializing in producing personalized bike parts to develop many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes another metal that is very light in weight and has additional hints terrific machining qualities due to its high mechanical stamina. This product may be created right into virtually any kind of shape and maintains its dimensions well. Also mission-critical parts that require a high level of accuracy might take advantage of their use.

The 30-Second Trick For Motorcycle Parts New Zealand Specialists

Another metal that sees hefty usage in the production of CNC-customized elements is magnesium. It is amongst the lightest read more metals that are now accessible and has excellent machinability attributes and stamina proportionate with its low weight. One of the disadvantages of magnesium is that its dirt might easily catch fire.

Due to its exceptional machinability and weldability, stainless-steel is an alloy that is particularly appropriate for CNC procedures. They have fantastic rust resistance and a high aesthetic charm. Their most typical use in producing numerous motorcycle components is fasteners, such as screws and bolts. Their reduced sensitivity to oxidation and deterioration makes them suitable for this usage.

Not known Incorrect Statements About Motorcycle Parts New Zealand Specialists

It seems that CNC turning and milling are the foundational procedures. In enhancement, it needs maintaining bars of product, most frequently plastic or steel, in setting and then turning a cutting device to eliminate sections of the product as the product is transformed.

These approaches are similarly vital and create elements with high precision and regular high quality. They are specifically: grinding, laser cutting, and exploration. The term "surface coating" refers to post-processes after the initial machining phase. Motorcycle Parts New Zealand Specialists. The processes help boost the total high quality of the machined bike elements. Below are the brief introduction, advantages and disadvantages of five surface area therapy techniques.

Facts About Motorcycle Parts New Zealand Specialists Revealed

Comments on “The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing”